Professor Bouzek receives an honorary mention from Czech Science Foundation Presidium chair

“Allow me to congratulate you on your excellent scientific results.” A recent letter from the chair of the Czech Science Foundation (CSF) Presidium opens with these words, announcing to UCT Prague Professor Karl Bouzek that he had received an honourable mention award for the excellent outputs of the “Electrochemistry of Pt – P oxoacids interface as a key to understanding of high temperature PEM fuel cells performance” project. Only ten projects financed by CSF each year receive this award.

“We wanted to gain a deeper understanding of the complex problem of the redox processes of phosphorus oxoacids on the surface of platinum catalyst under conditions corresponding to the operating conditions of a high-temperature fuel cell with a proton-conducting polymer electrolyte membrane, and thus help its optimize its application,” said Professor Bouzek in a short interview.

With whom did you collaborate on the project?

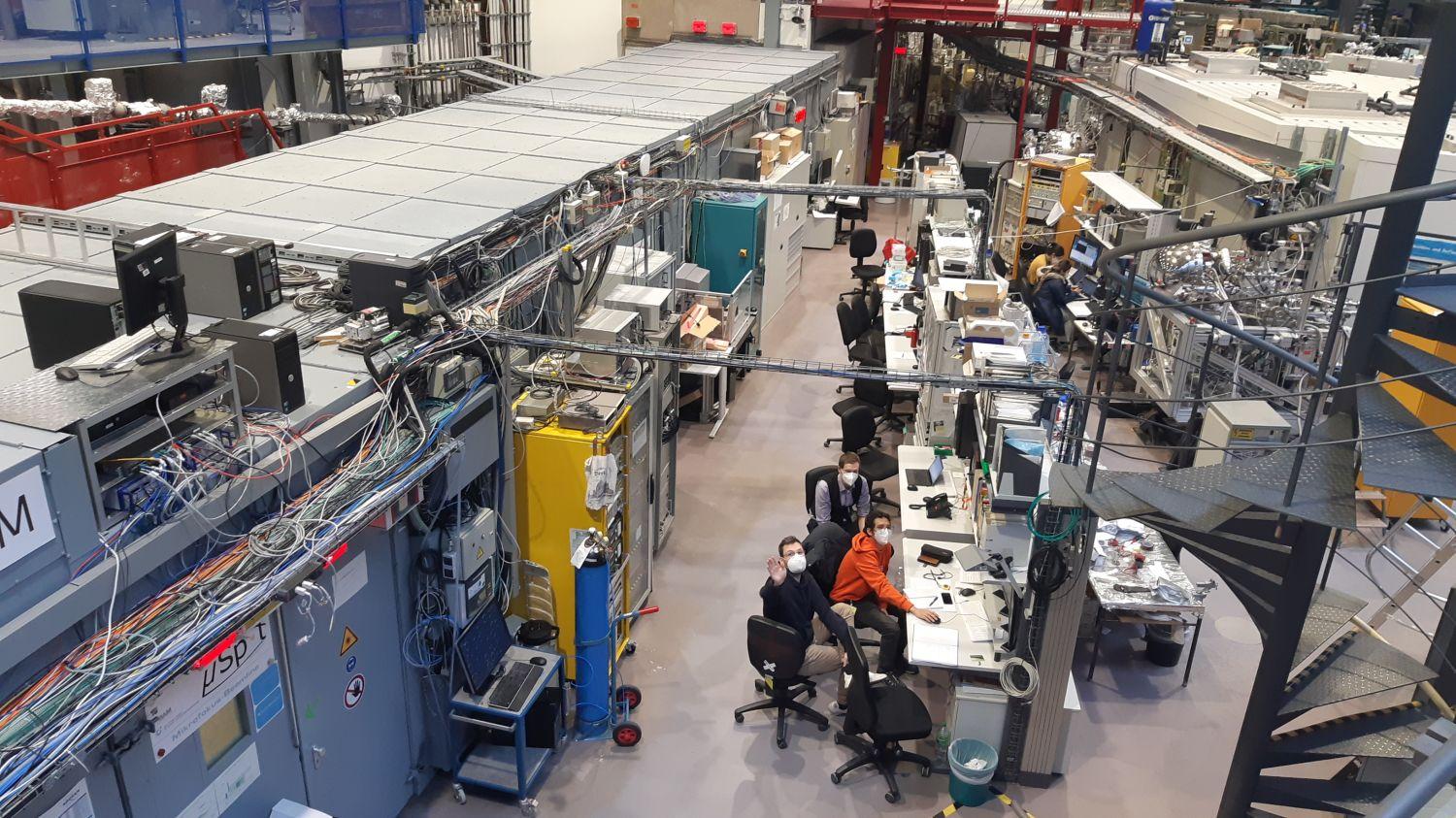

It was a bilateral project with partners from Germany: the Helmholtz-Zentrum Berlin (which, among other things, operates the BESSY synchrotron) and the University of Bayreuth, with expertise in the field of spectroscopic methods for the characterization of electrochemical processes during operation, the so-called in operando characterisation. In the last ten years or so, the development in the field of high-temperature PEM fuel cells has been slightly delayed due to higher demands on precious metals loadings. It is due to their faster degradation during operation. But now this technology experiences a certain renaissance. This is primarily due to the working temperature, which for this type of cells typically reaches 160 to 180 degrees Celsius. This temperature, when compared to the standard low-temperature fuel cells, significantly facilitates solution of the thermal management, i.e. the removal of the heat generated by the system. Therefore, there is also a growing interest in understanding the interaction of the catalyst with the electrolyte used and harnessing this to bring high-temperature PEM technology closer to the demands on precious metals and the lifetime of a low-temperature one.

Did you face any major issues?

The project was funded for three years. Just after its first year, COVID started. Before COVID, during the first year, we had prepared measurement methodologies, experimental fuel cells, and we were preparing detailed plans for experiments. And in this moment suddenly everything closed. So, it was not until the final six months of the grant (2022 – editor’s note) that we could really start measuring. Nevertheless, we obtained results that are obviously interesting. Otherwise quite prestigious journals would not accept them for publication. In this context, I would like to highlight the fantastic commitment shown by colleagues from our group, mainly Tomáš Bystroň and Martin Prokop.

Which journals have published your results?

ACS Catalysis is probably the most prestigious one. Despite that, I’m still upset that we wasted a year and a half waiting for the infrastructure to be open for us. We could have reached completely different amount and quality of results with this grant. We’ve now submitted an application for a follow-up grant and we will see if we have a chance continue to investigate this topic at such a level.

How do you explain that you won an award even though COVID changed your plans?

I find that very interesting; the results were probably sufficient (smiles).

So, what did you discover that the editors of ACS Catalysis wanted to publish?

A high-temperature cell operates at approximately 180 degrees Celsius. So, traditional polymer electrolytes used in the low-temperature fuel cells cannot be used. It is because their stability and ionic conductivity, as their functional properties are limited to their fully hydrated stay. For this reason, a polymeric carrier saturated with phosphoric acid is currently used as an electrolyte. However, in addition to the necessary ionic conductivity, it is also an environment interesting at the given temperatures in other respects. This is either because of its aggressiveness towards metals, or from the point of view of the chemistry of the central phosphorus atom, which is able to change oxidation states from – 3 to + 5. Each of its states interacts with the catalyst, most often platinum, on different way. Additionally, some of its oxoanions can also change the configuration of the molecule with temperature, which then has also different interaction. Some potential interactions of the electrolyte with the catalyst emerged from the classical electrochemical measurements we did before; we have now identified under real operational conditions more closely what is actually happening on the cathode and anode side of this system. We also identified some of the types of interactions with the catalyst under different conditions. Thanks to our findings, it is possible to avoid to some extent stress conditions leading to faster degradation or loss of fuel cell performance.

Do you think the renaissance of high-temperature cells will continue?

Hard to say, but it is definitely perspective technology. In the case of the low-temperature fuel cells, it was already thought, everything is solved and ready for commercial application. But especially in the field of mobility situation is more complex. In case of cars of various sizes, or for example airplanes, fuel cells produce, in addition to the desired electrical energy in hundreds of kilowatts, a corresponding amount of heat energy. If this heat energy has a potential of 50, 60 degrees Celsius, then in hot weather the radiator, dissipating hundreds of kilowatts at a temperature difference of 20, 30 degrees, must be enormously large. In case of working temperature of 180 degrees Celsius or higher, a compact radiator is fully sufficient because the temperature gradients driving the heat exchange with the environment is of 100 degrees higher. A number of car producers are now trying to figure out how to get to higher temperatures to facilitate the thermal management design of the entire powertrain.

You mentioned that you would have liked to have had more project outputs. What did you miss due to the pandemic?

We primarily intended to move towards alternative catalysts reducing the demands on the platinum metals and thus making the technology more economically competitive.

A few days ago, your research group had a kick-off meeting for another European grant under the M-ERA.Net program. What will you investigate?

ERA.Net generally focuses on smaller-scale international research projects, typically involving institutions from three to four countries. For the past two years, the priorities of the program focused, among other topics, on a clean energy and hydrogen technologies. In 2022, we received funding for developing of the industrial printing techniques for high-capacity production of fuel cells with structured properties coordinated by Fraunhofer Institute ENAS (Chemnitz, Germany). We have had good results with this project so far. Pleasantly encouraged, we successfully submitted another grant application, this time on the topic of water electrolysis as a source of so-called green hydrogen. The project is coordinated by the Mittweida University of Applied Sciences (Germany), and other partners are the Fraunhofer Institute in Dresden (Germany), the Polytechnic University of Timişoara (Romania), and also LEANCAT (a Czech company). We are primarily targeting the anode as the most demanding part of the water electrolysis system. Colleagues at the Fraunhofer Institute have succeeded in developing a new approach to the production of the basic component of the anode in this process, namely the so-called porous transport layer, based on titanium. This leads to significant material savings, but at the same time, opens up new ways to more efficient use the iridium-based catalyst. And this is where our primary activity is headed, designing these kinds of production procedures that reduce the demands of technology on precious metals while maintaining their basic advantages. Colleagues in Timișoara are dealing with the issue of recycling iridium and titanium so that they can be used in new units with minimal losses after the end of a electrolyser useful life.